|

Archives

October 2007

November 2007

December 2007

January 2008

February 2008

March 2008

April 2008

May 2008

June 2008

July 2008

August 2008

Sept-Nov 2008

December 2008

Jan-Mar 2009

April 2009

May 2009

June 2009

Jul-Sept 2009

Oct-Nov 2009

December 2009

January 2010

Return to Blog Index

Return to General Index

|

November 03, 2007

Rite of Passage, Backstage Access

| Click for larger images.

| I've got stuff. Lots of stuff. It fills up my home and my shop. One of the things that I've collected over the years is backstage passes. My occupation takes me to a lot of shows—sometimes two or three in a night. I've played and recorded professionally, made friends with a lot of musicians, and shared adventures with them while pursuing the "perfect" guitar. After a night out, I'd come home and throw the evening's pass, or passes into a box on a shelf in my coat closet. When the box got full, I'd put it away and start another one. I didn't think about it; I just collected those passes probably for the same reason I've collected all the other stuff—remember, I like stuff. I've also got a big box of guitar picks from those same shows, but that's another tale for the future.

|

| |

Once, a while back when I had fewer passes than now, a book publisher told me that I should do something with them, and I laughed. Who would want to look at a book full of passes? "It's your stories, man," he said. I ignored him. But here we are many years and two more boxes of passes later, and I'm dragging them out in no particular order to show you all, and tell a few stories. It's something I call my "Rite of Passage" because it really does document a life in guitars and my journey as a person. Here's the first one.

|

| Cell Phone in a Suitcase.

In February of 1991, Vernon Reid, the guitarist in Living Colour was in Chicago for a few days. It's a cool town, and there's plenty for a young man to do there. He'd rrecently been introduced to Tony Fitzpatrick, an artist whose artwork has been shown worldwide and has graced the covers of several Steve Earle releases. Tony is a colorful character who is engaging and intense. Vernon was drawn to the primitave imagery of Tony's work and wanted him to paint one of my Hamer guitars for him. The three of us were in Tony's studio, nailing down the concept for the guitar when I got a call from Jack Blades who was also in town with his wife. Jack mentioned that ZZ Top was playing in Indianapolis so even though it was snowing, I volunteered to drive; after all, it was only five hours away! After Jack made the necessary calls to secure passes, we all piled into my old Jaguar XJ6 and rolled out of town.

Jack is a ball of energy with a personality that is almost too big for one person. As we drove, he kept us all amused with stories from the road and gossip about all the people he knew—there wasn't a dull moment. To say that the banter was irreverent would be an understatement. I had one of those first Panasonic portable cell phones which was about the size of a briefcase and between stories, Jack asked to use it repeatedly to call friends or anyone he could think of like producer Ron Nevison or bandmate Tommy Shaw; "hey Tommy, it's Jack... guess where I am!"

| |

Vernon seemed at ease in the situation, but I couldn't help but wonder what he was thinking. He is a deeply reflective musician and artist who is the antithesis of the whole "rock star" stereotype so I'm imagining this scene was like the highway to hell for him. At one point, Jack called his manager in California and asked what his band's latest single was doing on the Billboard charts. The answer was really good news, and I looked in the rear view mirror to see Vernon shaking his head, clearly amused. With that, Vernon aptly summed up this perfect cliche of almost Spinal Tap proportions, chuckling in wry disbelief, "calling the manager from the Jag to check chart position." We all laughed so hard I nearly drove off the road.

We pulled into the arena lot and headed inside. Jack's big grin and hearty "dude" opened up the backstage area like Moses parting the sea, and we were welcomed like royalty. "This is Vernon Reid from Living Colour," he told everyone in earshot, which I found funny, because Vernon was on MTV every hour and was unmistakable. "And this is Jol Dantzig," he announced. "He makes the coolest guitars in the world for me." With that, Billy Gibbon's tech gave me the pass you see above and took me onstage to check out the guitar rig.

The main sound was coming from a tiny amp that was controlled from the mixing board and returned to stage monitors—I'd seen the same thing done on the Kiss stage among others. I played a few riffs on one of Billy's guitars and listened to it echo out over the seats.Then guys in the band showed up and introductions were made by Jack. Billy remembered me from his visit to our shop when we made some guitars for him. Frank Beard, the drummer disappeared with Jack while Vernon and I engaged Billy in some guitar shop-talk. After having some dinner in the backstage catering area, it was showtime and we were escorted out to the sound board to watch the set. I don't remember much about the show other than thinking that Gibbon's tone was pretty damn good for a big arena and that the lights were awesome.

About halfway through the show, Vernon was fading fast, and Jack had seen the set a half dozen times already, so we cut out early in anticipation of the long drive home. All the way back everybody took turns sleeping or trying to keep me awake with more funny stories. By the time we got back to Chicago, I was a zombie. Those were the days when I though nothing of driving ten hours and getting home at daybreak. I don't think I could stomach it now. Of course I say that until I pull the next stunt. I talked to Jack a few days ago, and he's just the same as always – "Hey man, can you make me a bass?"

|

|

November 07, 2007

Got Three Minibuckers and a Varitone...

|

|

OK, it's not really a varitone, but it does have the 16 position Tonestyler in it, along with three lucious Jason Lollar "Firebird" pickups. This sweet li'l tone machine is loaded with cool but subtle stuff. The boys over at Willcutt ordered up small batch of these guys in various colors, and we grabbed one before it left the shop and gave it a go through my 1965 vintage AC 10 twin. I had a hard time letting this one go; the minibuckers are a great match for the shimmer of the EL84s and the punchy attack of the twin 10" setup. These guitars are fully chambered with an "X" brace pattern that really opens up the sound. It also takes about 1.4 lbs. out of the weight so this one tipped the scales at 8 lbs even. I really love the understated ebony fingerboard with the minimalist inlays—we retained the full inlay at the 12th fret to give it the Hamer "brand" and I think that's a nice touch.

|

| The Tonestyler is a cool little device; I think it's a very useful system for a lot of instances where you need to find a space for your guitar in a mix. It has sixteen positions, with dedicated caps for each "click". It reminds me a little of using a parametric eq, only with a bunch of progressive presets. There's also a "true bypass" position that takes the loading out of the signal chain for those of you who can hear a dog whistle. We really enjoyed making these guitars, and the results were both beautiful to look at and killer to play. It was a fun exercise, and there are going to be a small group of very lucky (and happy) guitarists when these are gone.

|

|

November 12, 2007

November Tone Tip: Winterize Your Sound

|

All this talk about mini-humbuckers got me thinking about a lesson I learned a long time ago. I used to hate the firebird pickups—too thin and twangy for my humbucker-centric taste at the time. I owned a bunch of reverse 'Birds, but never could quite figure them out. I had a single pickup version that I liked, but the two and three pickup ones were something of a mystery. Then, around 1971 I did some work on Johnny Winter's Firebird to stop it from squealing at high volume. I showed him how to put a piece of foam behind the pickup to stop it from resonating. Problem solved.

|

| In return, he showed me a little trick to get a killer sound out of the neck pickup by turning the amp (in this case a Marshall 100w, but it works with almost any amp) on full treble/mid/presence and NO bass. Then he used the neck pickup with the tone control rolled off. Instant Winter-tone! Try it yourself.

| |

| November 15, 2007

The Boys (with Brazilian) are Back in Town

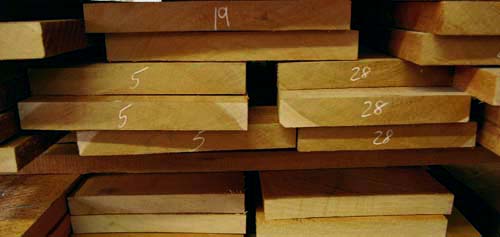

Some guitars get all the luck. Here you see Tom gloating over his work of the last few days; it's a matching headstock and fingerboard made from Brazilian rosewood over a nice clear limba neck.

This neck was started several months ago when Tom got Dave and Mike to help him cut some cured limba boards into 30 inch blanks. That's Dave manning the 24" swing saw, a ten horsepower brute that sounds like a jet engine when it runs free. We bought it back in 1980, and it was an antique then; having been made around the time of the second world war. Hey, what's better than vintage woodshop tools? I think I determined at some point that the blade's teeth are nearing the speed of sound, so that's where the whine comes from.

|

Tom consults the build sheet in preparation for bonding the fingerboard to the neck

| As the boards are cut, Tom selects each group of three matching pieces, and then numbers them so that they can be reassembled into a neck. This gives each neck the integrity of a single piece, with the structural advantage of opposing grain. As far as I'm concerned, this is the best of both worlds: a warp and twist-resistant neck with the resonance of a single piece. After the blank is glued up and roughed out on the bandsaw and shaper it gets the rosewood faceplate and fingerboard. Before we put a radius on the fingerboard, the neck will be put on a rack to "normalize" for several months. This allows any twisting to happen at this point instead of after the guitar gets made. We'll come back in a while to see how Dave does the binding next.

|

Tom marks each group while Dave and Mike cut the boards to length.

| Once the blanks are put together they can be roughed out to within a few hundredths of an inch of their final dimension. Then the fingerboard is bonded to the rough blank and the necks are set on a shelf to "normalize" for several months. Any twisting that happens will have run its course by the time we put the radius on the fingerboard, which means the playing surface (and the frets) are going to be straight... and stay that way for the life of the guitar.

|

These stacks of neck blank cuts are waiting to be ripped and glued.

| Sure, it's more time-consuming and expensive to wait for necks to cure; but in the long run it means a more uniform and trouble free guitar. This way, we take the natural changes out of the fingerboard—instead of the frets. Imagine that, a brand new guitar that didn't have to get a "fret-job" at the factory! That's because we're a workshop, and we don't cut corners with factory stuff.

|

Necks wait patiently to arrive at their final resting position before being radiused and fretted.

|

November22, 2007

Food, Thanks, and SRV on the Cover

| |

Some holidays are better than others. And, although the one at the end of the year usually brings stockings full of tube screamers and NOS Mullard EL84s, it's really Thanksgiving that I like the best. We're having some friends over for some food and laughter. At some point the guitars will come out and the tweed and blackface boxes will get switched on. Our full bellies will slow the tempo to an Otis Rush-perfect beat; rising to a shuffle as our dessert-and-espresso infused blood courses through our veins.

It's times like these that I am thankful for being able to share my passion for music and guitars with the people in my life. I'm thankful for a career that lets me do what I love. I'm thankful for the support of a great team of artisans upon whose shoulders I stand each and every day. I'm thankful for the total support of my friends and family, who don't beg me to get a "real" job. I'm a lucky guy indeed.

|

| |

A short time ago, I spent a little time on the phone with the editors of Premier Guitar magazine. They were recording a podcast to coincide with their review of a Talladega (the issue with SRV and Lenny on the cover) and there was no script. When I hung up the phone I wondered if the essence of what we do in the shop came across, or if I had just wasted their time. I guess you'll have to decide for yourself... I'm going back to the jam.

|

November 26, 2007

Earthly Bodies: Guitar Progress Report

|

| The earthen maple guitar prototypes are progressing right on schedule. Tom and Dave have built the necks, which are resting peacefully on the shelf while we experiment with the body configuration. I'm concerned about getting the right amount of warmth and openness to go along with the ring that I hear in the top material. As I mentioned before, these mineral-laced tops have a timbre that accentuates the snap, so it will be a matter of tuning the chamber to build some foundation underneath.

|

Two figured maple tops set up in the clamps.

| The backs are African Limba, and I've prepared three of them with different chamber sizes to get an idea of which direction to go. The one you see on the left has the normal chamber we use on guitars like the Artist model. That will represent the middle ground, while the one on the right has an exaggerated upper chamber with an additional lower cavity. This one is the opposite extreme from the first (smaller) size that isn't shown in the photo.

|

African Limba backs are rough cut, then chambered.

| I've already placed my bet on how they will differ, but as to which one will be the ultimate direction for this run of guitars will only be determined when all the prototypes are finished. It will also be a matter of matching the sound of the guitar with the proper pickup to bring out its best qualities. To that end, Seymour is cooking up some prototypes in his basement lab so we can fine tune them at that stage. I can't wait to hear the results.

|

Here are the three different bodies, glued and ready to be shaped.

|

|

November 30, 2007

When Handmade is Really Made by Hand

|

| I hear a lot of talk about "handmade" stuff. Handmade furniture, handmade burgers, handmade beer—yeah, right. I have to laugh sometimes. I imagine a giant brewery full of gleaming stainless steel vats the size of your average apartment house, churning out "micro-brew" by the cubic acre. The bottles have the image of some guy in a plaid shirt or an old log building on them, and that's supposed to make you think that it's "handmade." Isn't it amazing how you can go into any store in any town across the nation and find the same handmade items? That's a lot of hands.

This sort of reasoning crosses my mind often as I work in our little shop. Ten people all working with their hands. I'll look over at Mike Shishkov and see him using a chisel to finish up the control cavity on a one-off Watson model like the one above. He's concerned with the appearance and geometry of the individually angled sub-routs for each potentiometer. Each rout is tilted so the control emerges fromf the curved face of the guitar at a perfect 90 degree angle. It's a much more elegant (although time-consuming) solution than sanding a dimple in the top around the knobs.

|

Mike finishes up the control cavity with a hand chisel.

|

Moments before, he had finished blending the neck heel smoothly into the body using a spindle sander, scrapers and files. It's a precision task that takes around an hour, which is like a lifetime in the world of factory-produced guitars. I love the flow of the body where it meets the neck too. I guess these things don't really make a difference to a lot of folks; after all, it's just a tool. But in our case, it is also really made by hand. So, for those who actually want something made by human hands, it's nice to know that our work isn't just a marketing ploy.

|

This is the same Watson neck joint before Mike gets after it with the hand tools.

|

| Previous month

| Next month

| |

|